We provide

scientific and technology advances

in energy evolution for clean future

About us

PHYSGEO is a technology company that provides intelligent data driven solutions for oil&gas production.

We apply new science based optimization approaches and innovative products.

We apply new science based optimization approaches and innovative products.

experts and engineers

150+

complex projects

oil and gas fields surveyed

70+

180+

Typical challenges

Asset development strategy

Improving the efficiency of asset

Consultancy on non-standard problems

Uncertainties management and risk control

Values of our company

Key drivers of technological development

The most effective solutions for each project

Accumulation of knowledge and lessons learned within the company

people

technology

experience

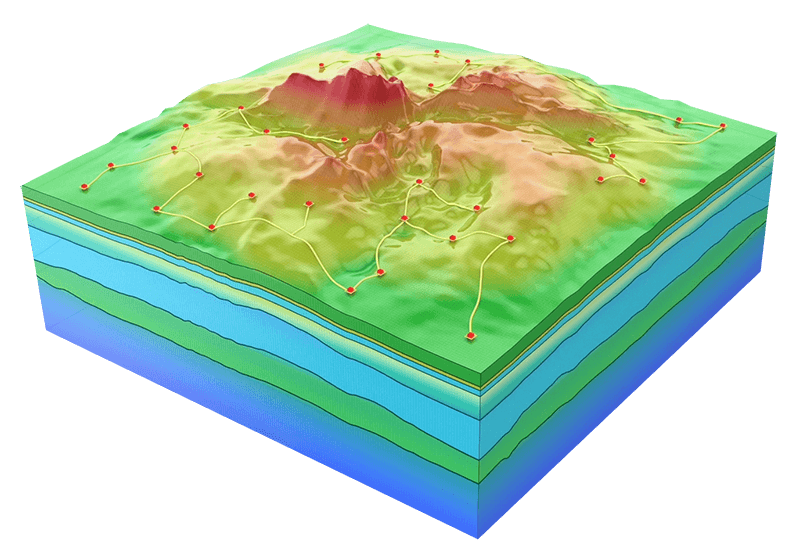

Wellbore geometry and trajectory optimization; prevention of mud losses, blow outs, control of cuttings volume, avoid natural faults if necessary

Drill faster and safe

Decrease risks of uncontrolled water intrusion

in reservoirs with faults

in reservoirs with faults

Increase well lifecycle

Assess the direction of permeability channeling

in fractured formations

in fractured formations

Avoid unwanted water or gas

Find fractured areas with better productivity,

plan trajectory and drill a well through these fractures

plan trajectory and drill a well through these fractures

Enhance production in tight fractured reservoirs

Prevent pollution of aquifers, reduce risks to surface infrastructure associated with subsidence and induced seismicity, select appropriate formations for re-injection of CO2 and drilling waste disposal

Reduce environmental impact

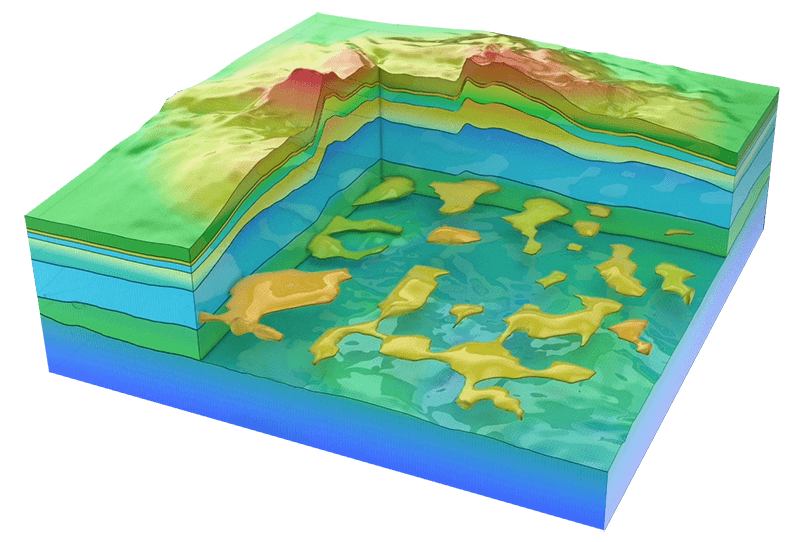

Study target zone geomechanics, select candidates for stimulation. Design fracturing treatment, including proppant and frac fluid type selection.

Avoid production of unwanted water or gas

Study key features of target zone.

Optimize hydraulic fracturing design.

Optimize hydraulic fracturing design.

Increase fractured well productivity

Develop a well stimulation approach, hydraulic fracturing design. Assist Customer and control/supervise treatment execution in the field.

Pilot projects

Reduce frequency of screen-outs, select suitable completion technology. Optimize proppant mass/fluid volume. Optimize hydraulic fracturing technology and frac fleet configuration.

Optimize OPEX

Report on quality during job execution in the field. Provide prompt recommendations in critical situations.

Ensure field implementation of technology

Detect key parameters affecting field development. Find technology application range based on multidimensional decision-making matrix

Define key concepts of field development

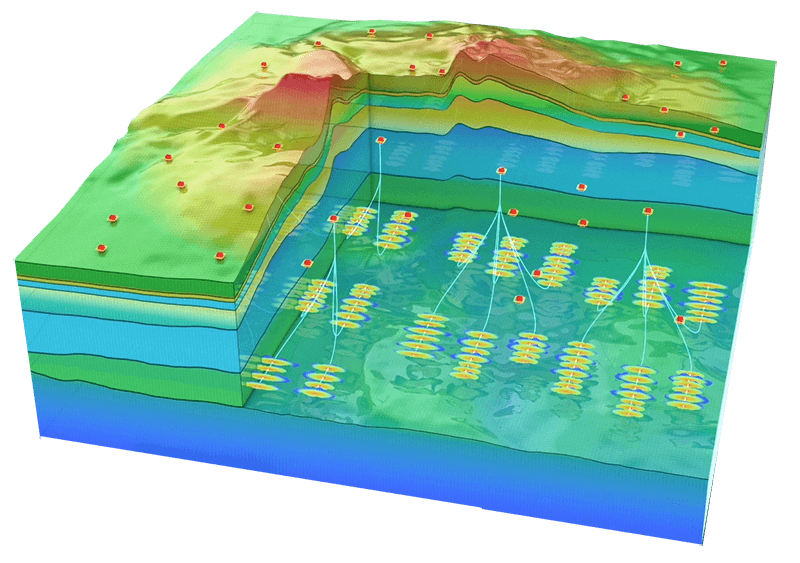

Select initial drilling areas. Determine optimal well designs and trajectories to improve efficiency. Optimize reservoir pressure maintenance system

Optimize efficiency of field development

Minimize risks during candidate selection and frac job execution. Rank decisions accordingly to their economic efficiency

Select the most effective well completion design

Select and assess optimal EOR techniques. Plan research program and apply experimental results during simulation. Perform sensitivity analysis of all EOR risks and uncertainties.

Evaluate efficiency of Enhanced Oil Recovery techniques

Automated multivariate comparison of well pad construction costs to well drilling costs

Determine location and optimal number of well pads

Consider local topography, land allocation, technological and regulatory restrictions while simulating field gathering system design/layout

Gathering system optimization

Based on current status, identify the potential for cost optimization

Feasibility studies for reconstruction/reengineering

Account for the asset development horizon according to the P10, P50, P90 scenarios and changes of extracted HC properties such as Water Cut increase, GOR change et cetera.

Evolution of surface facilities design for different development scenarios/technological parameters

Technology

Increasing field development profitability by multi-variant optimization approach

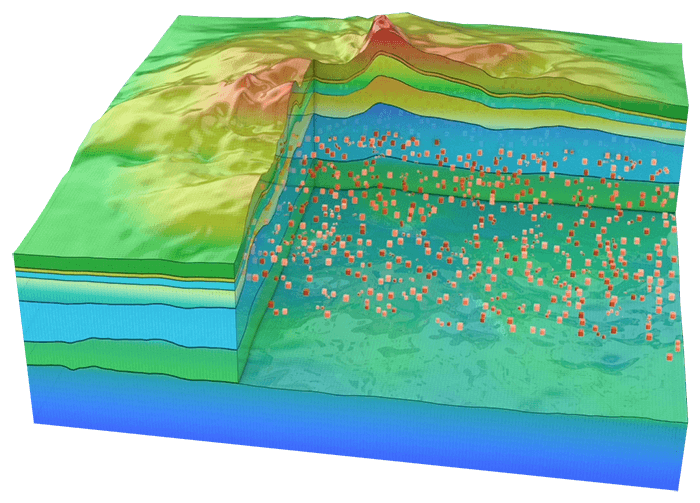

Ensemble based modeling

Optimal asset development strategy

Uncertainties minimization, technological and geological risks reduction

Decision-making matrix

Investment attractiveness of the asset

Products

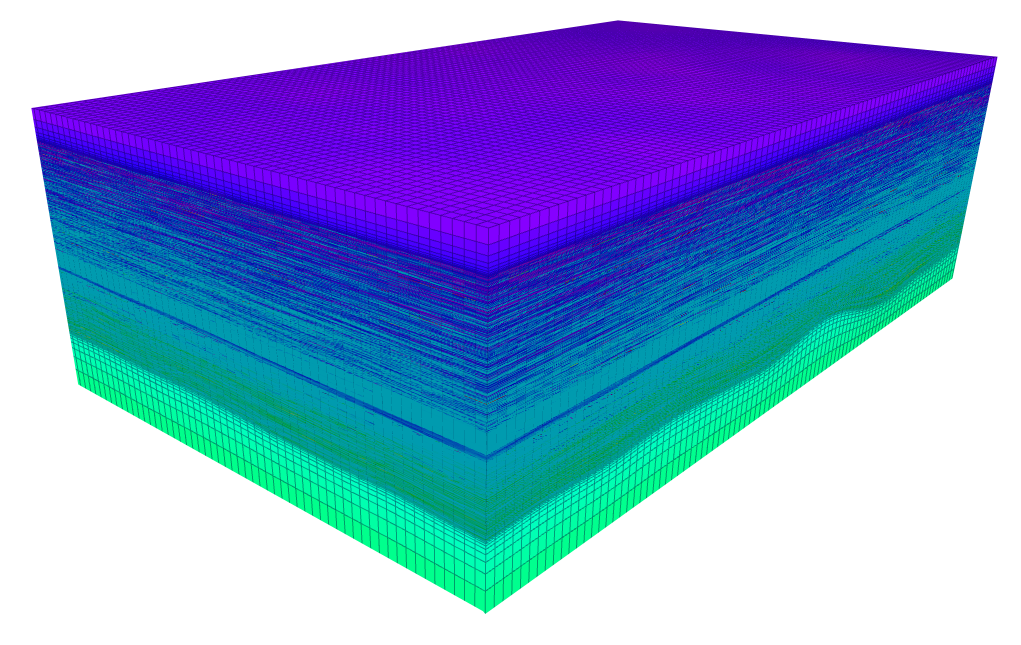

Gefest is designed to perform a full cycle of work: 1D, 3D, 4D geomechanical modeling of oil and gas fields. It is intended to assess in-situ stress state and its reaction to externally imposed changes to minimize drilling-associated risks, aid in field development and direct well stimulation

Geomechanical modeling software

Learn more

Contact us